Reed switch actuation

Decision criteria for choosing the right magnet

|

switch type desired switching characteristic switching distance way of movement dimensions, tolerances, weight |

temperature range surrounding materials mounting options existing space, etc. |

We will gladly help you to choose the right magnet

Technical information

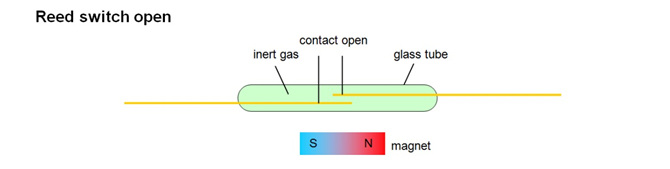

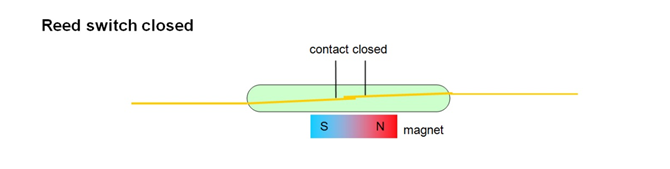

Reed switches can be used wherever switching operations are to be carried out without contact.

Basic element of the Reed switch, which is always magnetically actuated, is a pair of contact tips (reeds) made of ferromagnetic material. The contact tips are welded into an inert gas-filled glass tube.

When a magnet approaches the Reed switch and one of the contact tips is flooded with the N-pole and the other with the S-pole, the contact tips close. The contact tips open again when the magnet is removed or rotated so that both contact tips are flooded with the same pole (N or S).

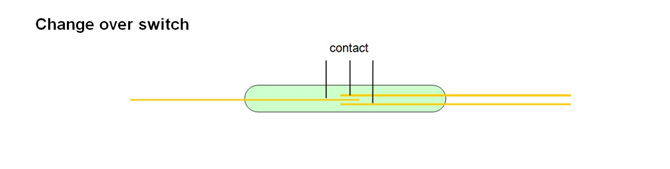

Another type of Reed switch (change-over switch) has 3 contact tips so that not only switching on and off is possible but also a change over.

Selection of the most important functional characteristics

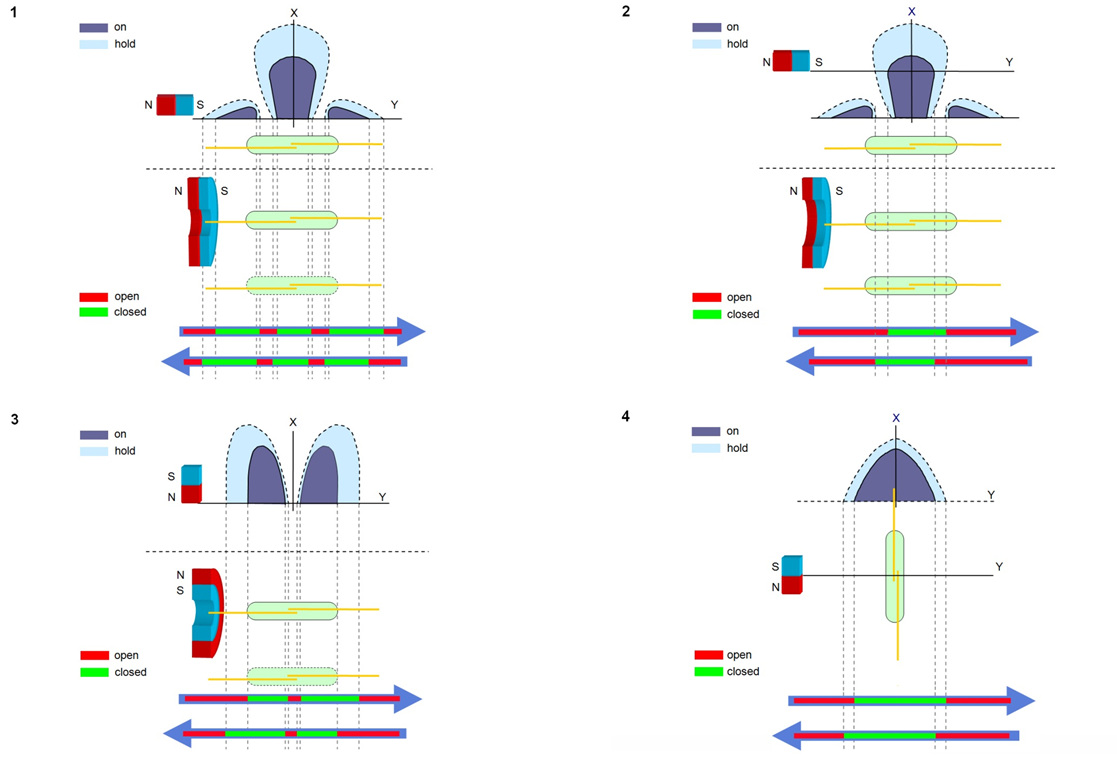

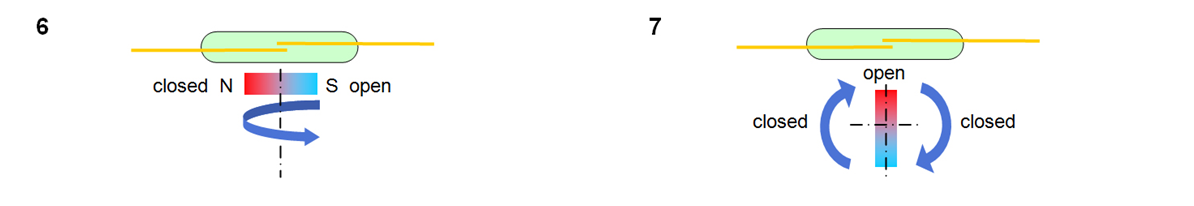

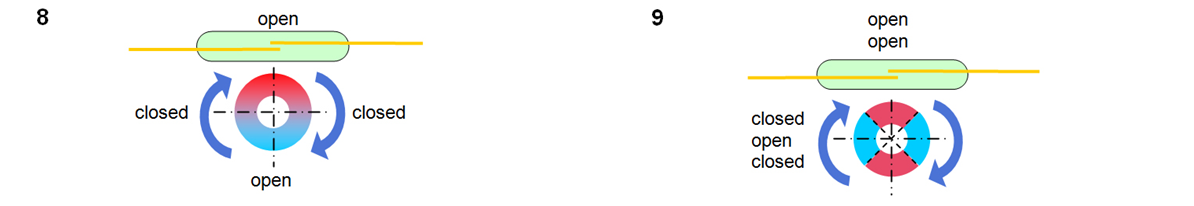

The drawings show how the different types of magnetization act on the Reed switches.

Selection of the most important Reed switch operations

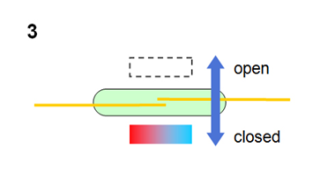

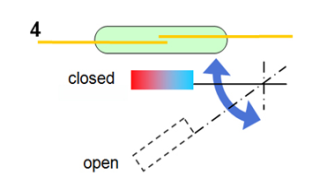

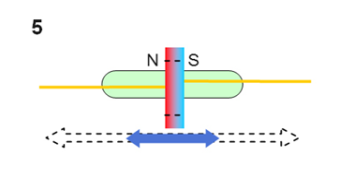

Approach movement

In all systems listed here, the Reed switch and magnet must be close enough to each other. The sensitivity of the switch and the field strength of the magnet determine the distance between the switch and the magnet. Corresponding approach or removals of the magnet determine the closing or opening of the contact tips. The distance of the magnet to the switch is always lower for closing the contacts than that at which the contacts open again.

A magnet moved perpendicular to the Reed switch. The switch closes only once, at maximum magnet displacement.

A magnet moved parallel to the Reed switch. The switch closes up to three times at maximum magnet displacement and once at minimum displacement.

A magnet operated horizontally to the switch longitudinal axis. The magnet moves this time at right angles to the switch longitudinal axis. The switch closes only once.

A magnet in swiveling motion to the reed switch. The magnet must be moved at a large angle so that the switch closes once.

A ring magnet in parallel movement to the Reed switch can have up to three closing points at maximum displacement or one closing point with minimum displacement.

Rotation

Following are some typical applications where different magnets are in rotation:

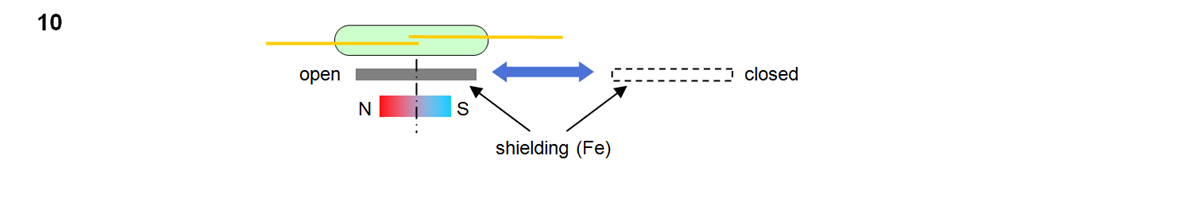

Shielding

With the stationary arrangement of a Reed switch and magnet, the contact tips are closed. If the magnetic field is diverted through a shield made of ferromagnetic material, which is pushed between the magnet and the switch, the contact tips open again. By completely removing the shield, the contact tips are again magnetically actuated and close.

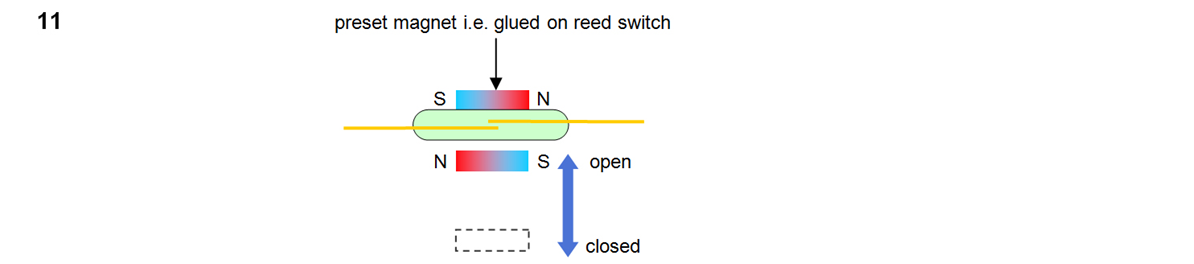

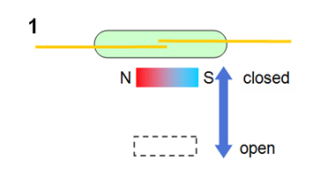

Magnetic preload

This effect is achieved by bringing a magnet close to the switch, keeping it closed (normally closed contact). If a second magnet with reversed polarity or a coil with a stronger field is moved to the switch, the switch opens again, as the magnetic lines of force cancel each other.