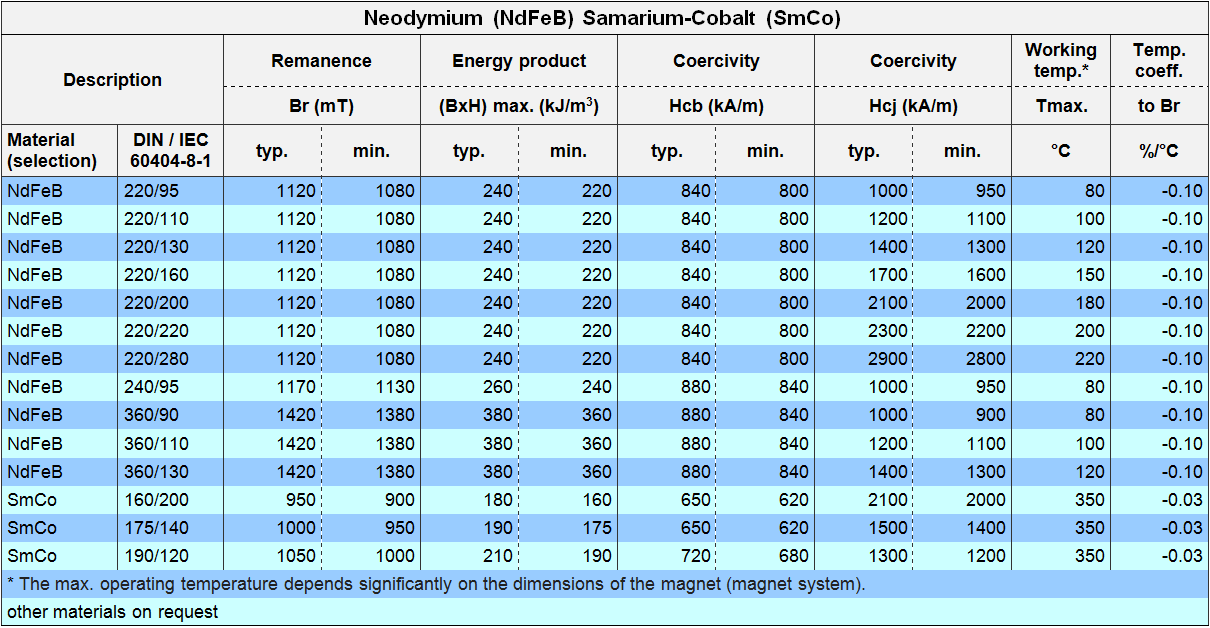

Material information

Useful information

Neodymium and Samarium-Cobalt magnets are high energy permanent magnets and consist mainly of alloys of rare earth metals (neodymium, samarium) and other metals (e.g., iron, cobalt).

The most common shapes are square, disc, ring and segment magnets. However, other shapes can be made.

Like all sintered metals, rare-earth magnets, in particular SmCo magnets, are very hard and brittle and are therefore sensitive to impacts.

At low temperatures, SmCo magnets are relatively resistant to moisture, solvents and alkalis, but not to acids and salt solutions. NdFeB magnets corrode in moisture and react strongly to acids and salt solutions. By galvanic or other coatings, the magnets can be protected against corrosion.

Because of their high hardness a mechanical machining of sintered rare earth magnets is only possible with diamond tools.

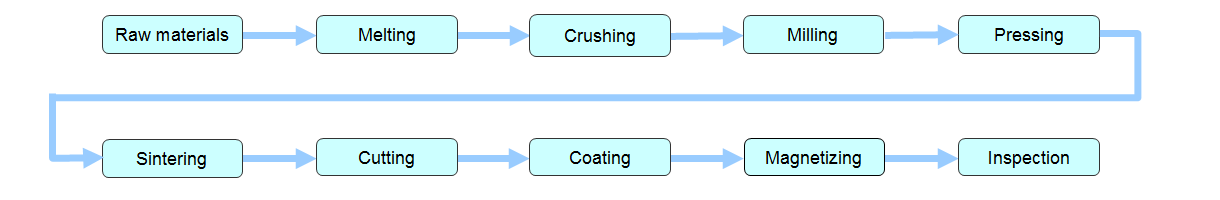

Process flow